Background

Hastings Deering is Australia’s largest Caterpillar dealership supplying Caterpillar equipment (big yellow earth moving machines) to the construction and mining industries throughout Queensland and the Northern Territory.

The major revenue sources comes from after market parts & services, especially parts sales.

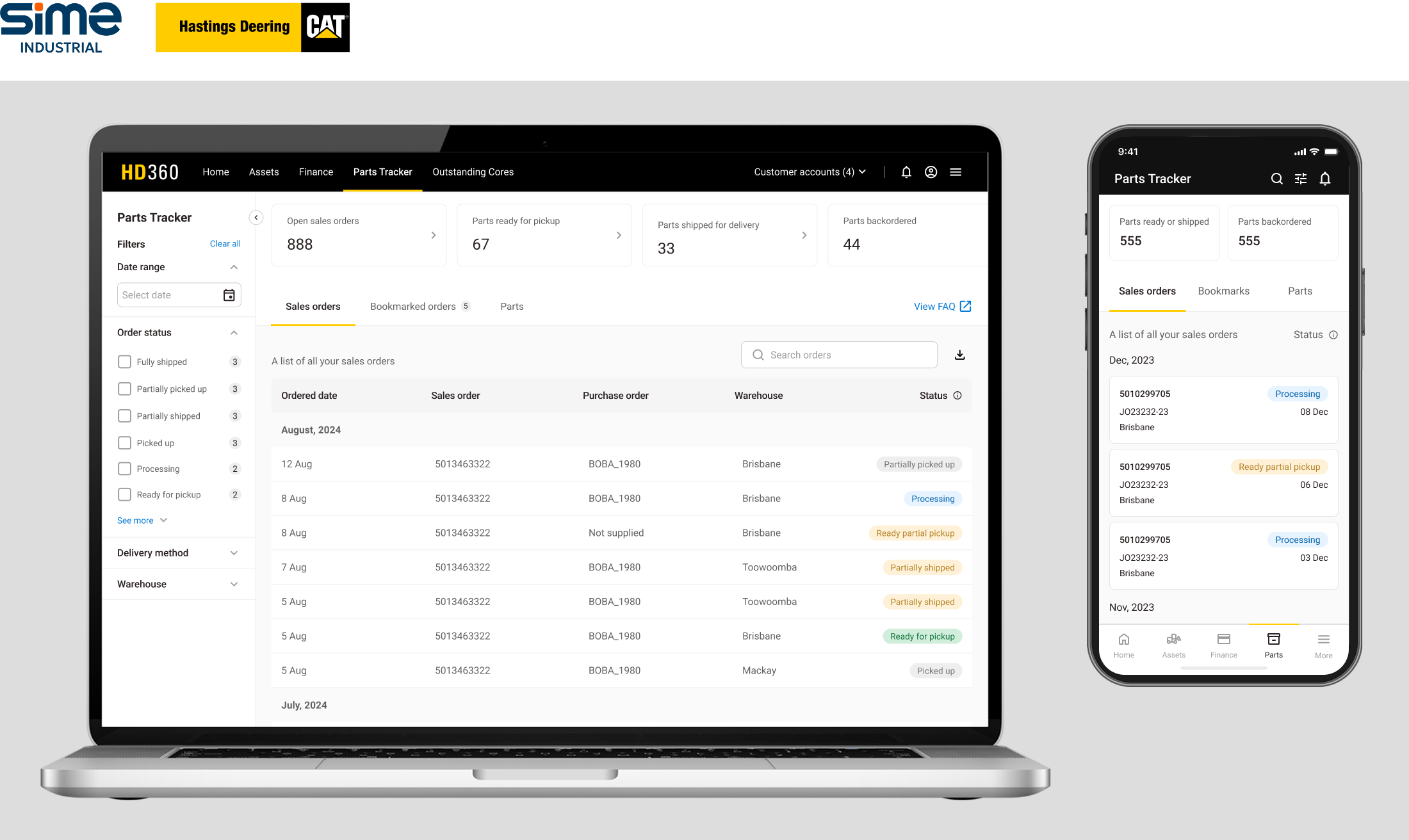

The customer app allows Hastings Deering customers to track machine health, machine location, service schedules, credit limit and invoicing and track the status of their parts order.

My Role

I led the end-to-end design of this feature including the following;

- User research: I planned and conducted research with customers and stakeholders.

- Lead UX/UI design: Including, user-flows, wireframing, prototyping, user testing iterations and final UI design.

- On a cross-functional agile team I collaborate closely with product owners, business analysts, technical, QA and customer support teams to ensure the best customer experience and meet business goals.

- Facilitated workshops with cross functional team and stakeholders using human-centred design methodologies.

- Monitor: Gather feedback back from CX teams, Customer support channels and follow up research to continuously improve the product.

Product Release

The Challenge

Hastings Deering customers had very little visibility on the status of their parts orders which lead to an overload of calls to the customer support phone line. In order to alleviate the pressure on the support lines a proof of concept tool called Parts Tracker was created to allow customer to look up the status of an order.

This was a simple search page however the issue was that many customers had multiple sales orders in progress at any one time which made this feature cumbersome to use.

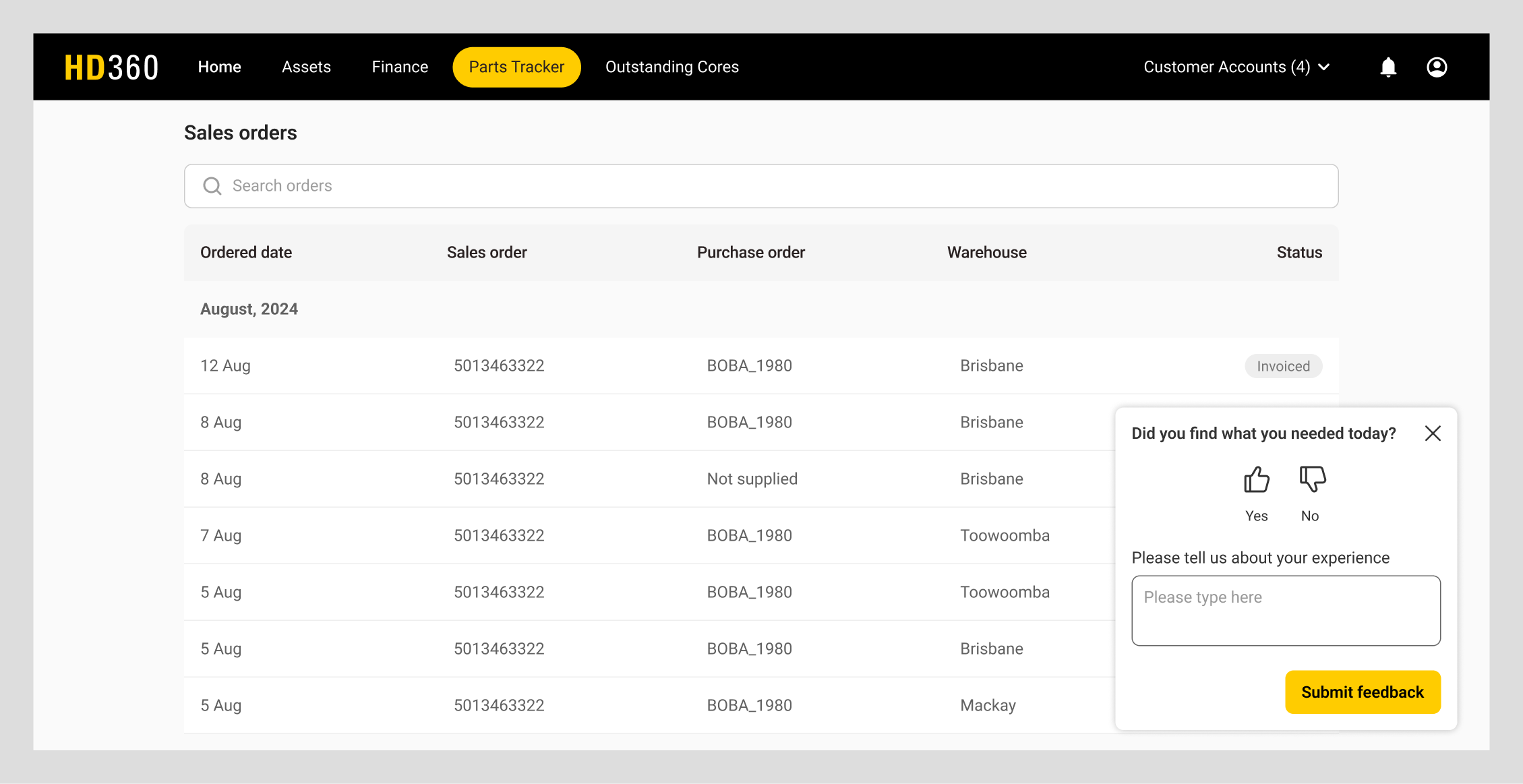

Customer feedback via phone support and a in-app feedback widget was often negative with customers stating the feature did not meet their needs and would prefer talking to someone on the phone.

It was decided that a new version of Parts Tracker was needed, one that addressed the needs of the customer that would also cut down phones calls to customer support.

Proof of Concept (version 1.0)

User Research

Methodologies used

- 1 on 1 interviews (customers & business SMEs)

- In-app surveys

- Customer support phone data

- Service safaris

I planned and conducted a series of customers interviews to get a deeper understanding of the challenges they have running their business and what impact a lack of visibility on parts availability has on them.

This combined with feedback from customer support teams and in-app feedback widgets gave me the below insights.

Research findings

- Lack of visibility on backorder parts caused maintenance scheduling issues and impacted income for customers.

- Incremental parts order fulfillment, due to parts availability, required frustrated customers to make multiple trips to the parts centre.

- Regional customers had to travel multiple hours to get to the parts centre only to be told not all parts are ready.

- Order status labels were too vague and misleading.

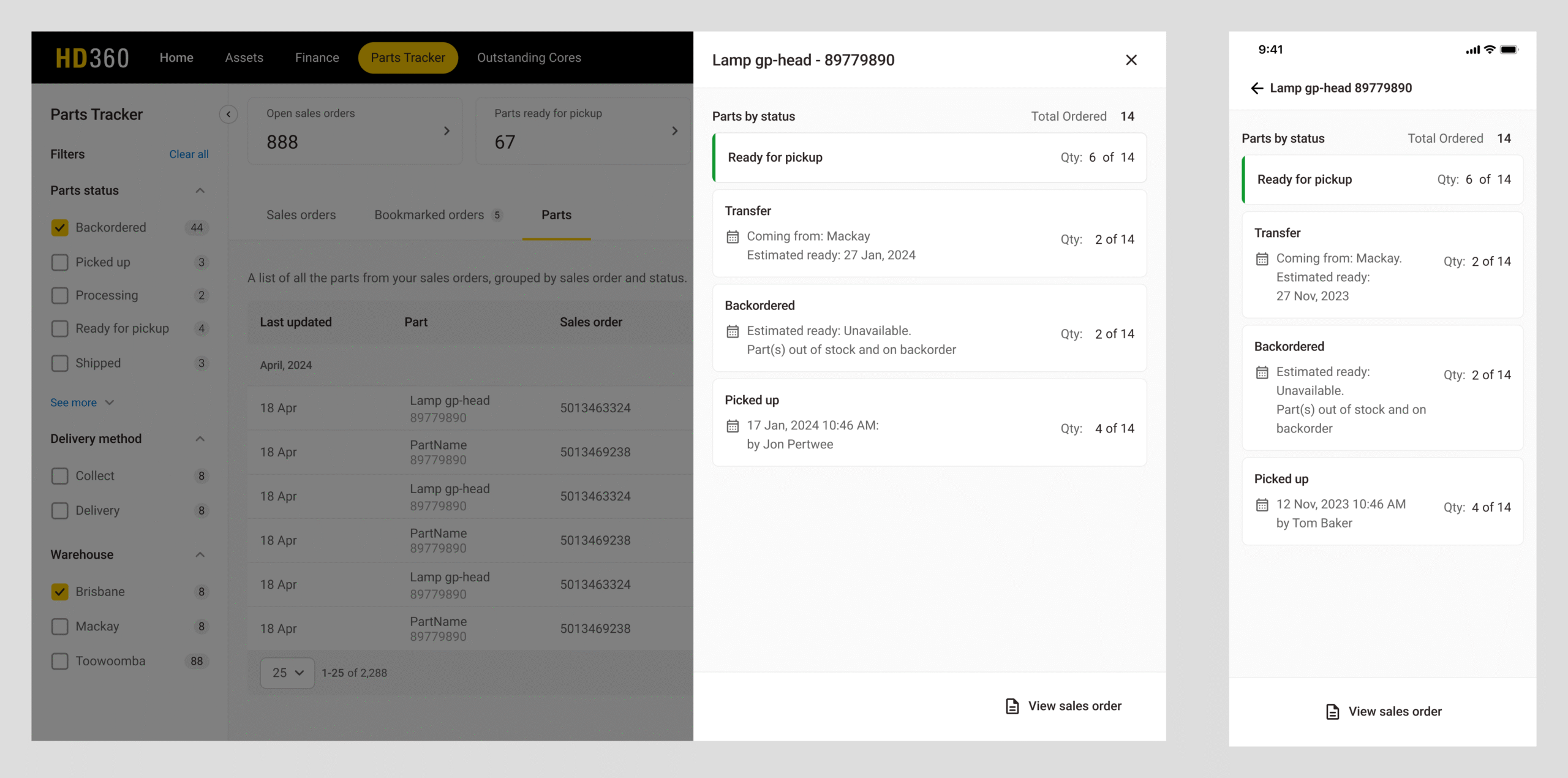

- Customers wanted to know where a part was coming from so they could better plan their time and expectations.

- Large volume customers found it difficult to get an holistic view of all their parts availability.

Recommendations

- Allow customer to quickly and easily get backorder details.

- Show parts in a timeline of availability so they can decide/plan their time.

- Show customers what city/country backordered parts are coming from.

- Create more informative sales order status labels.

- Send customers order status updates via notifications.

Design

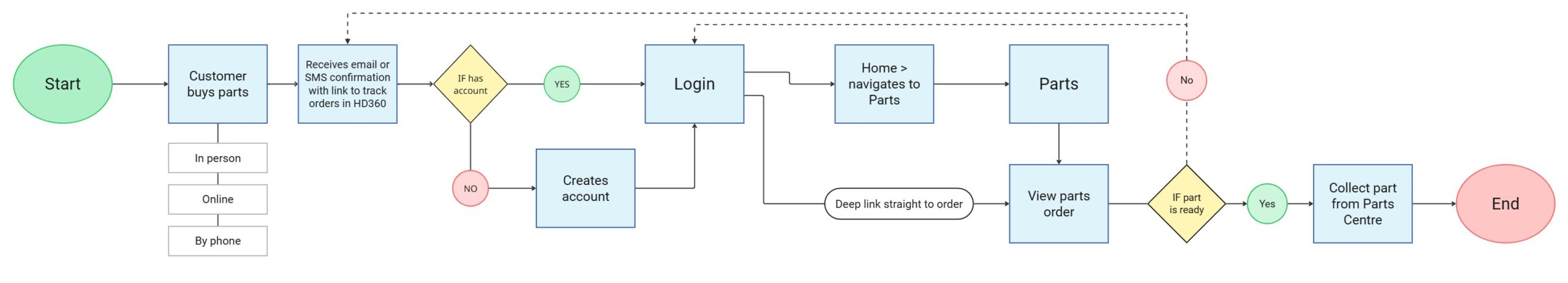

User-flow

I started out by mapping the customer flow from buying a part through to accessing the app and tracking the status of their parts order.

Considerations were given as to whether they did or did not have an HD360 account.

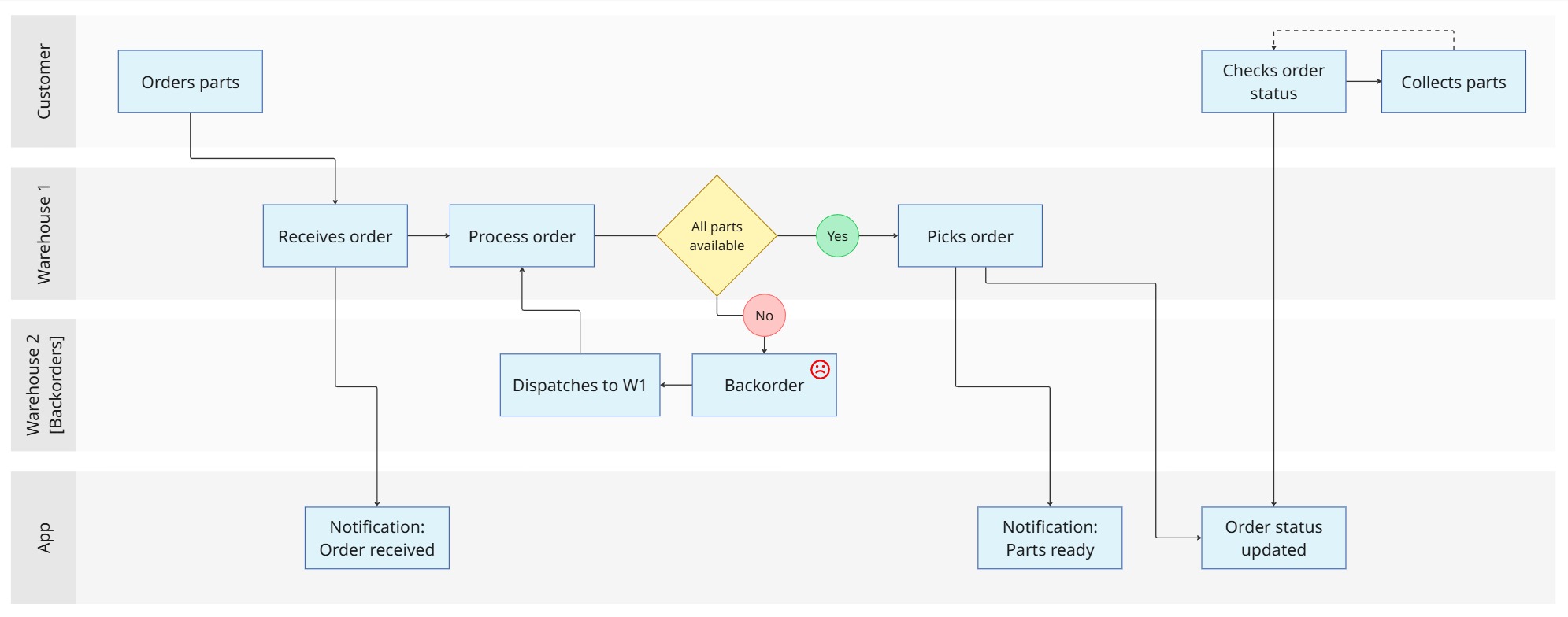

Next I wanted to map out the flow that incorporates the business flow from the warehouse, considerations were given for what happens when a part is put on back order, a major pain point for customers.

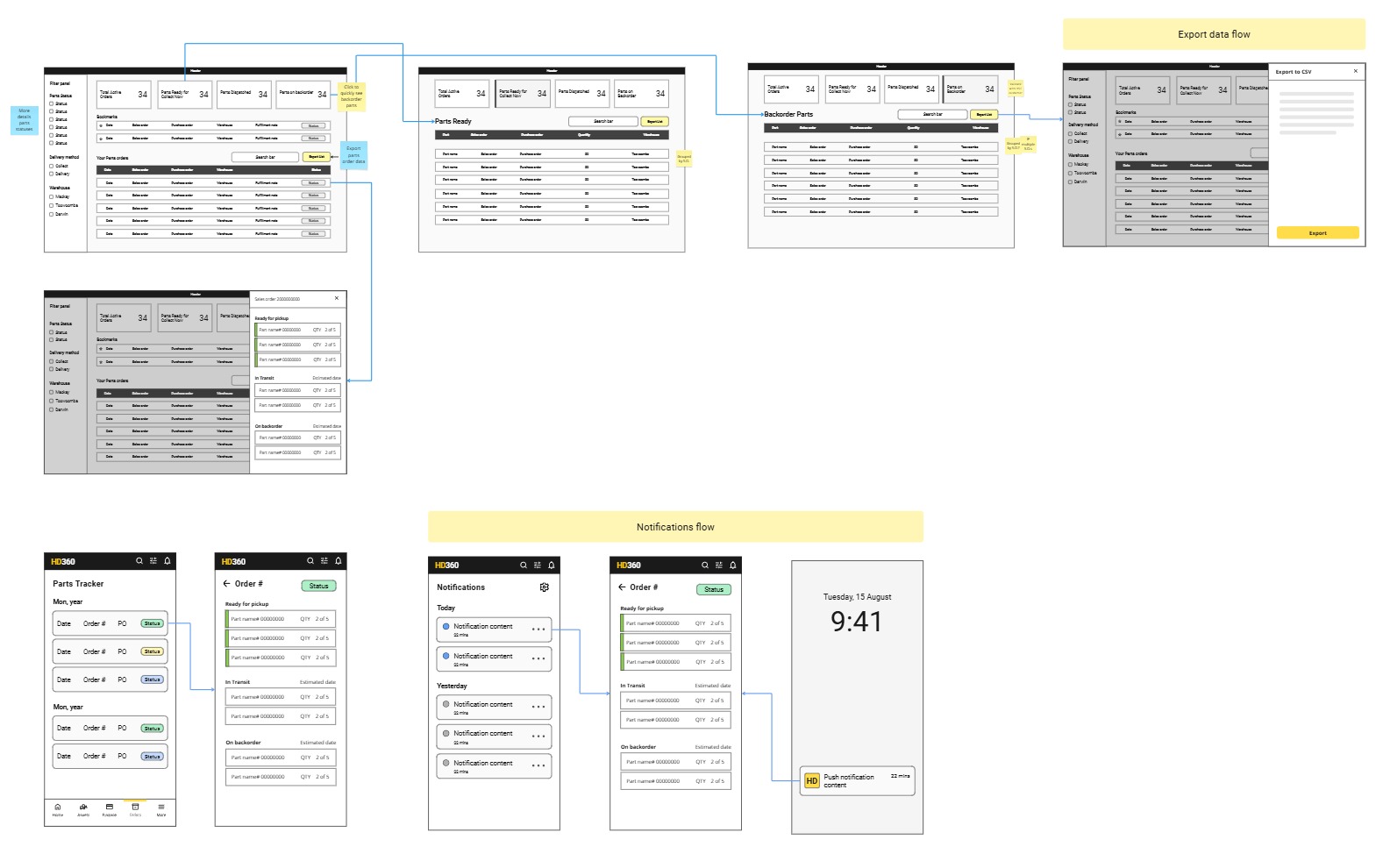

Wireframes

Low fidelity wireframes were created to work through the flow and to validate with customers and stakeholders via a series of workshops.

Validation sessions were conduction in person and over MS Teams utilising Figma prototypes for both web and mobile.

UI Design

Based on the research I focused my redesign on 3 key areas.

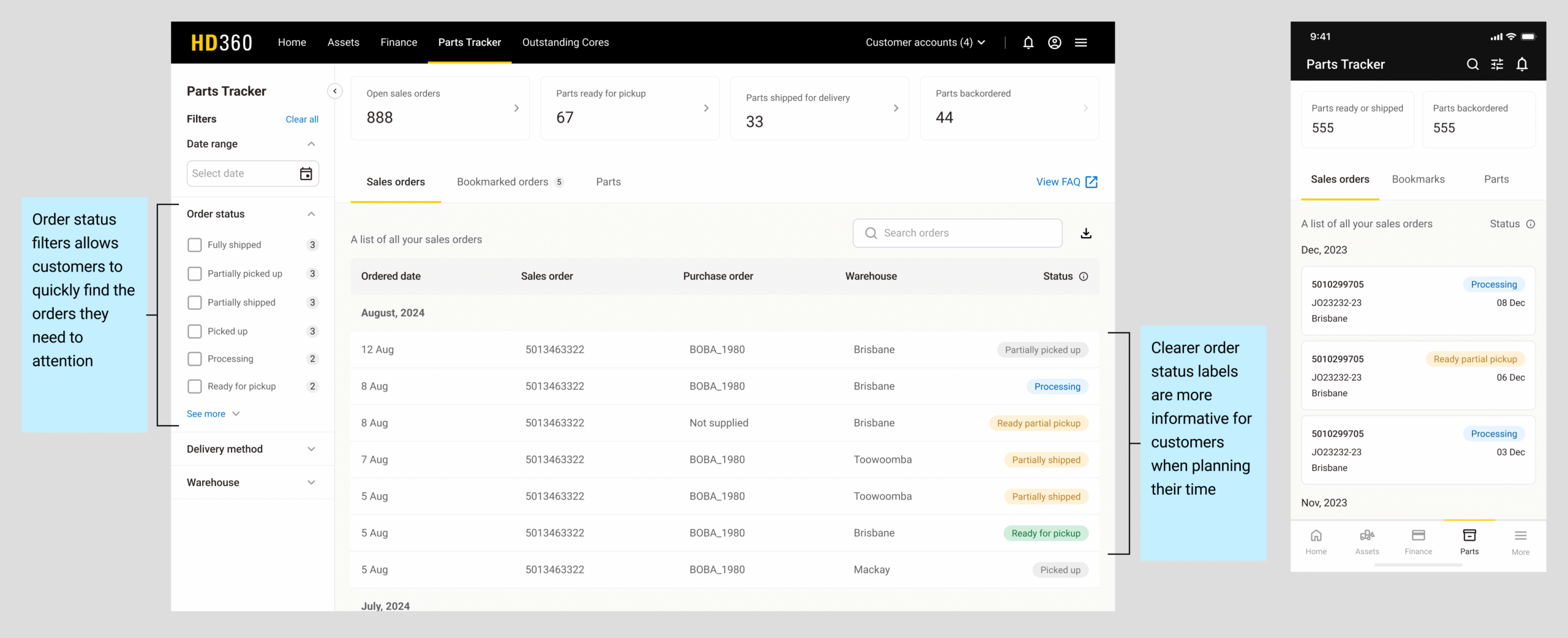

- Reviewing the order status labels to tell the customer more detailed about the fulfillment on an order

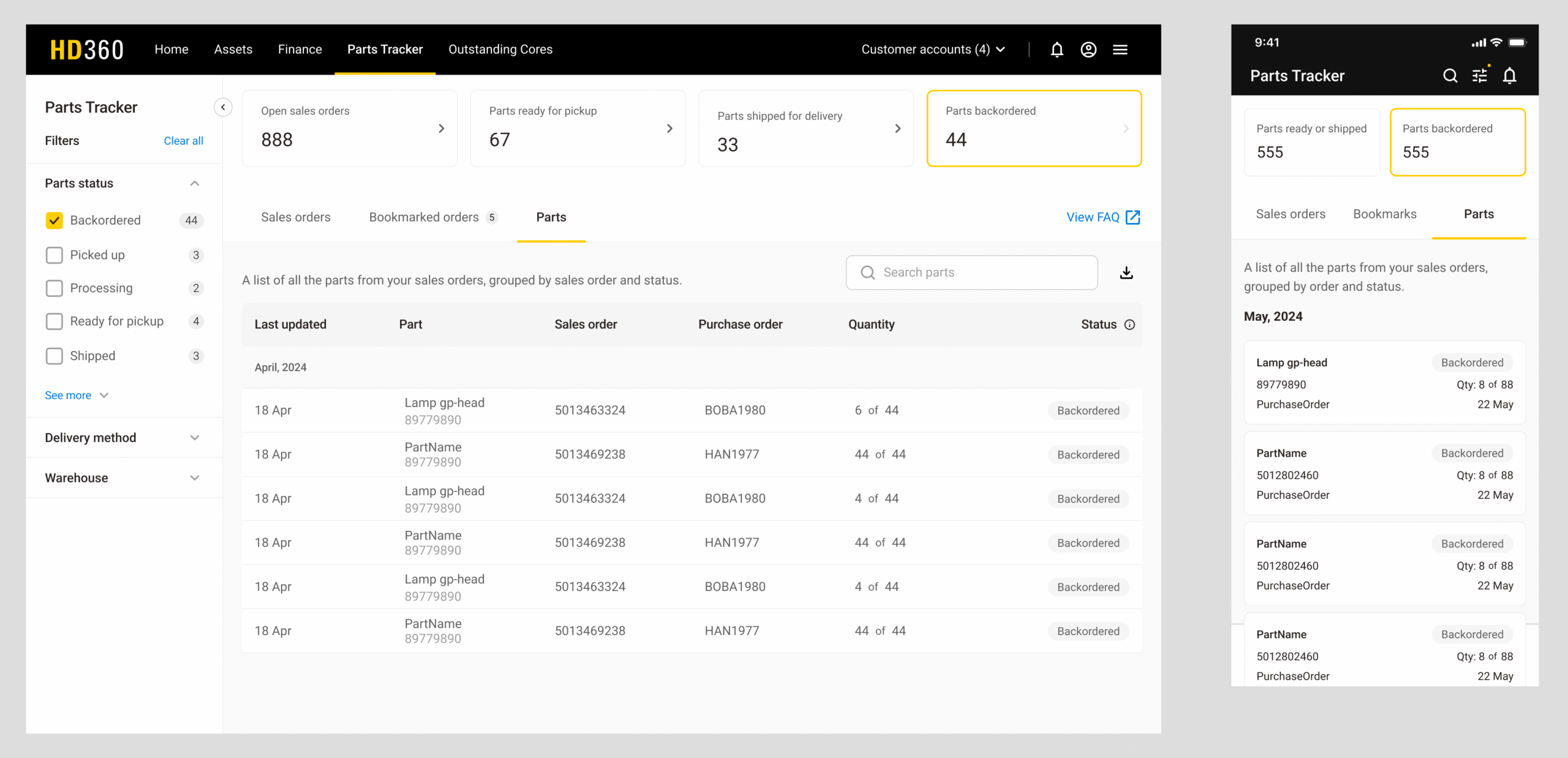

- Presenting the parts by ‘what is ready and not ready’ which would allow the customer to plan their time better

- Creating high level snapshots that gave large volume customers a quick view of where all their parts were.

Parts Order Statuses

A new set of order statuses were created to quickly tell if an order was partially or fully ready for pickup or delivery.

Customers with a large volume of orders could filter their orders by status and a color chip system was implemented to allow customers to quickly and easily identity which orders were fully ready or not.

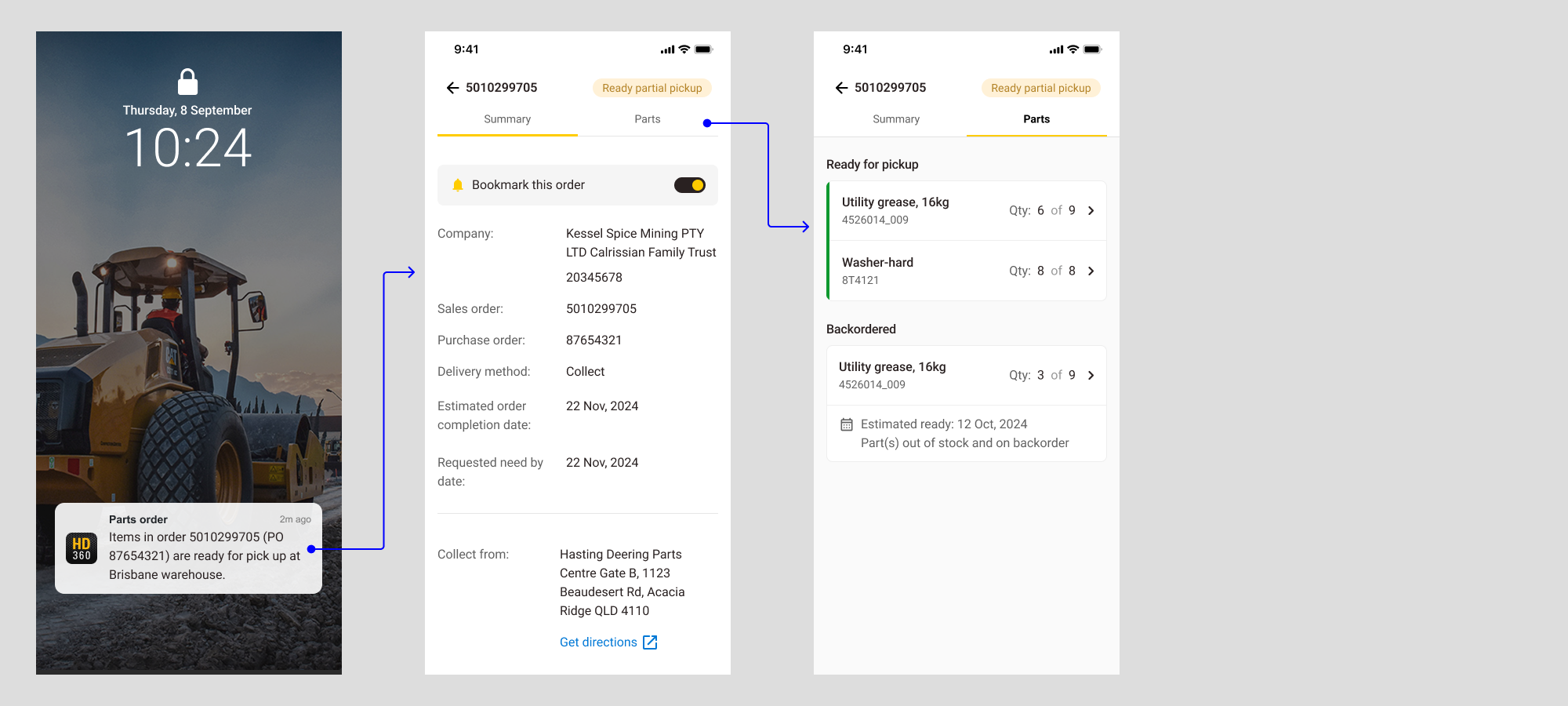

Orders details screen

The parts were grouped by their availability status, customers said “I just wanted to know what is ready and not ready”. Parts available now at the top with parts on back order at the bottom.

Snapshots

The snapshots were designed to give the customers a quick high level view of where their parts orders are at.

The customer can click on them to give them a filter list of parts that match the category, then export to CSV for further analysis withing their own reporting systems.

Push notifications

Customers are time poor and replacement parts are often urgent, push notifications via the mobile app were crucial in communicating quickly to the customer that their parts were ready.

Impact

Adoption

- Parts Tracker drives 67% of HD360’s active customer adoption

- 37,374 Unique parts orders tracked in last 12 months

110.7% increase from previous 12 months

Customer Feedback

Post release I reached out to some customers to get their feedback on the new parts tracking features.

- “I have reviewed the updates and I like the additional information we can obtain in this system that can really reduce the unnecessary phone calls with this new visibility”

- “I find HD360 app very easy to use and find parts tracking especially handy because it is much easier for us to look in the app than to go through all our emails. “

- “the new [parts] status tab on the parts order screen is a game changer for us”